Sun SPARCstation IPC - PSU Recapping Photos

Some photos taken while recapping the PSU in my SPARCstation IPC. The whole process only took around two hours with the help of the desoldering gun and temperature controlled soldering iron. Click a picture to embiggen.

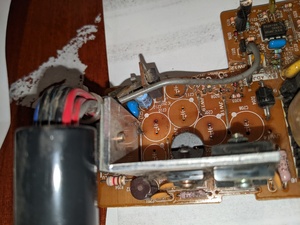

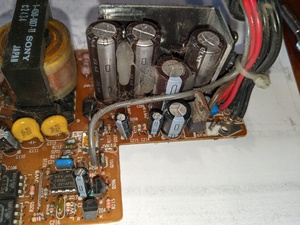

Before

The PSU looks fine and doesn't smell, but it also doesn't work.

Pre-right |

PCB Removed, right |

PCB, pre, left |

PCB, pre, center |

PCB, pre, left, 2 |

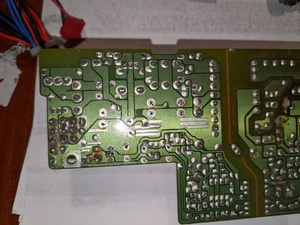

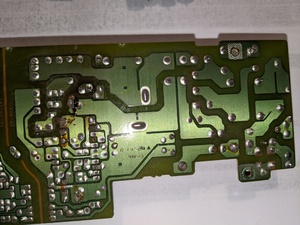

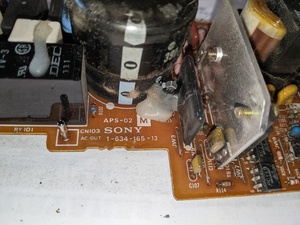

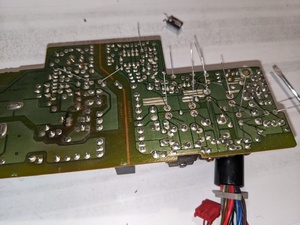

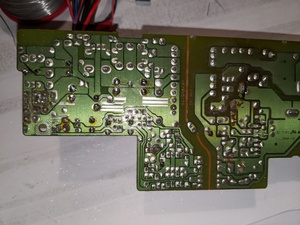

PCB, Pre, Left, Underside |

PCB, Pre, Center, Underside |

PCB, Pre, Right, Underside |

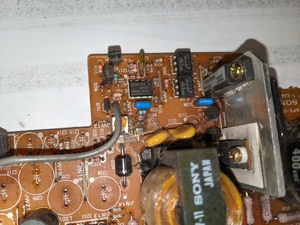

Desoldering

Most aluminimum electrolytic capacitors were desoldered (all the ones I had replacements on hand for, the few I left behind appeared fine) with a desoldering gun. With capacitors C208, C209, C211 and C210 removed a faint smell of electrolyte was detectable and there is visible discolouration on the PCB.

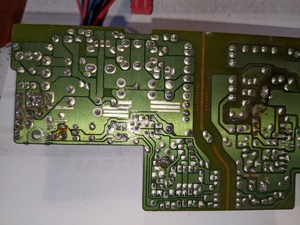

Installing New Capacitors

Next the new capacitors were installed - pretty easy.

PCB, Left, Caps Installed |

PCB, Caps installed |

PCB, Top, Caps installed |

PCB, Soldered, 1 |

PCB, soldered, 2 |

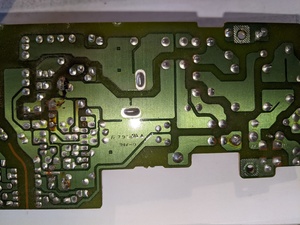

PCB, Left, Done |

PCB, Left, Done, 2 |

Assembled

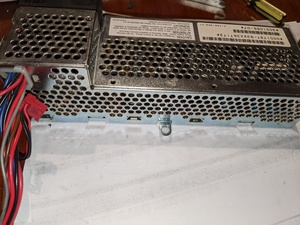

Then the PSU was reassembled and tested. First powerup was outside with just a hard disk connected in case something went bang. There was no smoke so the system was reassembled and it started up successfully for the first time in years.

Assembly, 1 |

Assembly, 2 |

Assembly, 3 |

Assembled, 1 |

Assembled, 2 |

Assembled, 3 |

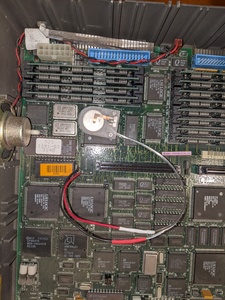

New Battery |

Tested |